What Best Practices Ensure Effective Marine Deck Machinery Repair?

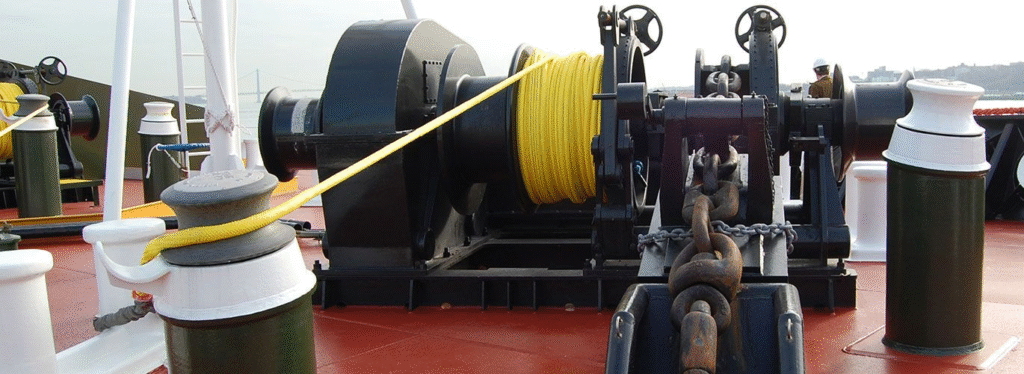

Marine deck machinery plays a critical role in ensuring the safe and efficient operation of vessels. From mooring winches and cranes to capstans and windlasses, these mechanical systems handle some of the most physically demanding tasks onboard ships. Given their importance, effective maintenance and repair are essential to avoid operational failures, costly downtime, and safety hazards. Implementing best practices in marine deck machinery repair ensures that vessels remain seaworthy and operational efficiency is maintained. This article explores the most effective practices, highlighting methods, procedures, and safety considerations for optimal results.

Understanding Marine Deck Machinery and Its Importance

Marine deck machinery encompasses a variety of equipment used on the deck of a vessel for handling cargo, anchors, and mooring operations. Common types include:

- Mooring winches – used for tying the ship to a dock.

- Capstans and windlasses – for handling anchors and heavy ropes.

- Cranes and derricks – for cargo lifting and loading operations.

- Hydraulic systems – for powering winches, cranes, and other machinery.

These systems endure high loads and continuous usage, often under harsh maritime conditions such as saltwater exposure, humidity, and extreme temperatures. Any malfunction can directly impact vessel safety, crew efficiency, and operational timelines. Therefore, adopting best practices in repair and maintenance is crucial for minimizing risks and maximizing the lifespan of marine deck machinery.

NOTE:- Marine Deck Machinery Repair was successfully handled by Power Hydraulics for multiple maritime clients. Our team replaced faulty machinery, calibrated systems, and restored peak performance. Each repair was completed on time with attention to detail. Contact Power Hydraulics immediately to ensure your Marine Deck Machinery Repair meets professional standards.

Conducting Comprehensive Inspections

A cornerstone of effective repair is thorough inspection. Before any maintenance or repair work begins, machinery must be carefully assessed to identify issues and underlying causes.

Visual Inspection

Visual inspection is the first step in identifying obvious defects such as corrosion, cracks, wear, and loose fasteners. Inspectors should focus on:

- Structural integrity – checking for cracks, deformation, or metal fatigue.

- Surface conditions – monitoring signs of rust or corrosion.

- Hydraulic and electrical components – ensuring hoses, wires, and connectors are intact.

Operational Testing

Beyond visual checks, machinery should undergo operational testing to detect performance issues not visible externally. This includes:

- Running motors and winches under no-load and partial-load conditions.

- Checking for unusual vibrations, noise, or resistance.

- Verifying hydraulic pressure, flow rates, and operational smoothness.

Using Advanced Diagnostic Tools

Modern diagnostic tools can significantly enhance inspection accuracy. Ultrasonic testing, thermal imaging, and vibration analysis allow for early detection of faults such as internal wear, overheating, and misalignment.

Following Manufacturer Guidelines and Standards

Marine deck machinery is designed with specific operational limits and maintenance requirements outlined by manufacturers. Adhering strictly to these guidelines ensures repairs are performed correctly and machinery longevity is preserved.

Technical Manuals

Maintenance manuals provide step-by-step procedures for servicing each component. Technicians should follow recommended torque settings, lubrication schedules, and component replacement intervals.

Regulatory Compliance

Many maritime authorities, such as the International Maritime Organization (IMO), set standards for vessel safety and equipment maintenance. Ensuring compliance with these regulations is vital to avoid penalties and maintain insurance validity.

Using Genuine Spare Parts

Whenever components need replacement, using manufacturer-approved spare parts is critical. Inferior parts can compromise machinery performance, lead to frequent breakdowns, and increase long-term costs.

Employing Skilled and Trained Personnel

The effectiveness of marine deck machinery repair heavily depends on the expertise of the personnel performing the work. Unskilled handling can worsen damage, create safety risks, and lead to operational downtime.

Technical Training

Technicians should receive specialized training in marine engineering and hydraulic systems. Understanding the mechanical and hydraulic principles behind the machinery enables precise troubleshooting and repair.

Safety Training

Deck machinery repair often involves working with heavy loads, electrical systems, and pressurized hydraulics. Proper safety training, including the use of personal protective equipment (PPE), lockout/tagout procedures, and emergency protocols, is essential.

Continuous Skill Development

Technological advancements in marine equipment mean that training must be ongoing. Regular workshops, certification courses, and updates on new machinery help technicians stay current and effective.

Implementing Preventive and Predictive Maintenance

Preventive and predictive maintenance are strategies designed to minimize unplanned downtime and extend machinery life.

Preventive Maintenance

Preventive maintenance involves scheduled inspections and servicing to prevent failures. Typical tasks include:

- Lubricating moving parts to reduce friction.

- Tightening bolts and fasteners.

- Cleaning machinery to remove salt and debris.

- Replacing worn-out components before failure occurs.

Predictive Maintenance

Predictive maintenance leverages data and monitoring systems to anticipate potential issues. Techniques include:

- Vibration analysis to detect imbalance or misalignment.

- Thermal imaging to monitor overheating components.

- Hydraulic fluid analysis to identify contamination or degradation.

By combining preventive and predictive approaches, vessels can maintain high operational reliability and reduce costly emergency repairs.

Ensuring Proper Lubrication and Hydraulics Management

Lubrication and hydraulic systems are integral to the smooth operation of deck machinery. Failure in these areas is a common cause of mechanical breakdowns.

Lubrication Practices

Correct lubrication reduces wear, friction, and corrosion. Best practices include:

- Using the appropriate type and grade of lubricant as per manufacturer recommendations.

- Applying lubricants at correct intervals.

- Ensuring that lubricants are clean and free from contaminants.

Hydraulic System Maintenance

Hydraulic systems require careful monitoring due to high-pressure operations. Key practices include:

- Regularly checking fluid levels and quality.

- Inspecting hoses and connections for leaks.

- Replacing hydraulic fluids as recommended.

- Monitoring system pressure to detect anomalies early.

Proper Alignment and Calibration

Misalignment of rotating machinery and improperly calibrated systems can accelerate wear and compromise safety. Alignment and calibration are essential for optimal performance.

Shaft and Drum Alignment

Winches, cranes, and other rotating equipment require precise shaft alignment to prevent vibrations, excessive wear, and premature failure. Laser alignment tools and dial indicators are commonly used for accuracy.

Sensor and Control Calibration

Modern marine deck machinery often includes electronic sensors and automated controls. Calibrating these systems ensures accurate load handling, safe operation, and efficient performance.

Keeping Detailed Maintenance Records

Documentation is an often-overlooked aspect of effective machinery repair. Maintaining comprehensive records helps in tracking performance, identifying recurring issues, and planning future maintenance.

Inspection Reports

Every inspection should be documented, including findings, corrective actions, and recommendations. These reports serve as a reference for future repairs.

Maintenance Logs

Logs should include dates of maintenance, types of service performed, replaced parts, and technicians involved. This history aids in warranty claims, audits, and regulatory compliance.

Performance Analysis

Analyzing historical maintenance data allows ship operators to detect trends, anticipate failures, and optimize repair schedules.

Emphasizing Safety and Risk Management

Marine deck machinery repair carries inherent risks due to heavy equipment, hydraulic pressures, and electrical systems. Safety should always be the top priority.

Hazard Identification

Before repair work begins, technicians should identify potential hazards such as pinch points, hot surfaces, high-pressure systems, and unstable loads.

Safe Work Procedures

Following standard operating procedures (SOPs) and lockout/tagout protocols reduces the likelihood of accidents. Proper scaffolding, harnesses, and tools are also essential.

Emergency Preparedness

Repair teams should have access to first aid, fire suppression equipment, and emergency shutdown mechanisms to respond promptly in case of incidents.

Leveraging Technology for Efficient Repairs

Advancements in technology have significantly improved the efficiency and effectiveness of marine deck machinery repair.

Computerized Maintenance Management Systems (CMMS)

CMMS software helps manage maintenance schedules, track work orders, and store repair history. This centralization improves efficiency and accountability.

Remote Monitoring

Some modern deck machinery is equipped with IoT sensors that allow remote monitoring of performance metrics. Early detection of anomalies can prevent breakdowns and optimize repair timing.

Simulation and Training Tools

Simulation software and virtual reality (VR) training allow technicians to practice complex repair procedures in a controlled environment, reducing errors and improving proficiency.

Conclusion

Effective marine deck machinery repair is vital for the safety, reliability, and efficiency of vessel operations. By implementing best practices such as thorough inspections, adherence to manufacturer guidelines, skilled personnel, preventive and predictive maintenance, proper lubrication, calibration, meticulous record-keeping, and safety protocols, ship operators can significantly reduce downtime and extend equipment life. Leveraging modern technologies like CMMS, remote monitoring, and simulation tools further enhances repair effectiveness, ensuring that vessels remain operational in the demanding maritime environment. A strategic, professional, and systematic approach to repair not only safeguards the vessel and crew but also contributes to the long-term operational and financial success of maritime operations.