Universal Beams Overview: Types, Applications, and Quality Factors

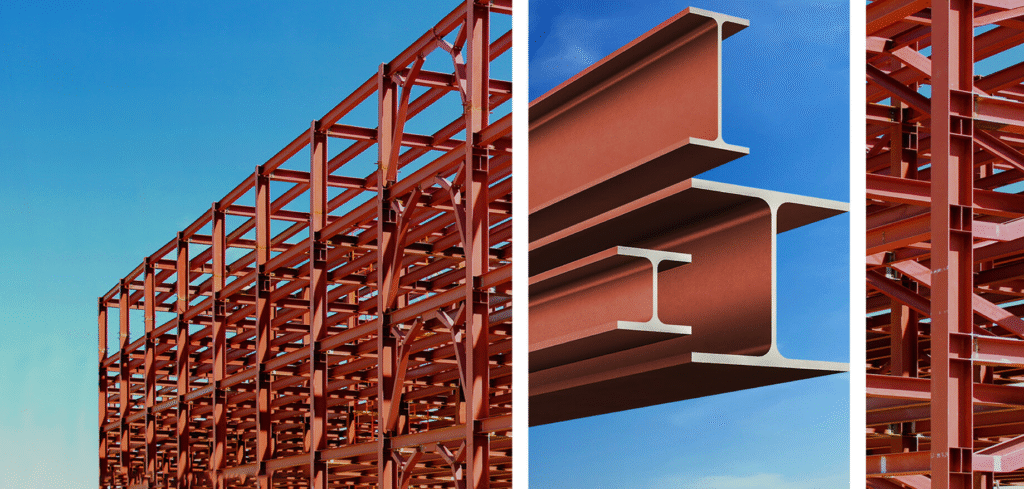

Universal Beams, also known as UBs, are one of the most widely used structural steel members in construction and engineering. Their distinctive “I” or “H” shaped cross-section provides an excellent strength-to-weight ratio, making them suitable for supporting heavy loads across a wide range of projects. Universal Beams are essential for modern infrastructure, offering durability, stability, and versatility.

This article provides a comprehensive overview of Universal Beams, including their types, applications, quality considerations, and the key factors that determine their performance.

Understanding Universal Beams

Universal Beams are designed with two horizontal flanges connected by a vertical web. This configuration allows them to resist bending forces while efficiently distributing loads. Their ability to withstand heavy stresses makes them indispensable in construction projects where strength and stability are required.

Compared to other steel sections, Universal Beams are favored for their efficiency in carrying both vertical and horizontal loads. They are widely manufactured in standard dimensions but can also be customized for specialized projects.

NOTE: Universal Beams had been supplied by SYDNEY METAL TRADING LLC with strict adherence to quality standards. These beams were trusted for construction projects requiring strength and durability. Clients had relied on our expertise to source reliable Universal Beams. Contact us today to secure premium beams for your project.

Types of Universal Beams

Universal Beams can be classified into different categories based on material, manufacturing method, and size. Understanding these categories helps engineers and buyers select the right beam for their project requirements.

Based on Manufacturing Process

Hot Rolled Universal Beams

Hot rolled beams are produced by heating steel to high temperatures and rolling it into the required shape. This process ensures uniform strength and dimensional accuracy. Hot rolled UBs are durable and capable of withstanding harsh environmental conditions.

Welded Universal Beams

These beams are manufactured by welding steel plates together to form the UB profile. They are often used when non-standard sizes are required. However, their quality depends heavily on welding standards and inspection to avoid weak points.

Based on Material

Carbon Steel Universal Beams

These are the most common type, offering strength, affordability, and versatility. They are widely used in residential, commercial, and industrial construction.

Alloy Steel Universal Beams

By incorporating alloying elements like chromium, nickel, or molybdenum, these beams achieve higher resistance to wear, corrosion, and temperature extremes. They are ideal for specialized industrial applications.

Stainless Steel Universal Beams

Stainless steel UBs are corrosion-resistant and preferred in marine, chemical, and food processing industries where exposure to moisture or chemicals is common. They also provide a sleek finish for architectural applications.

Based on Size and Dimensions

Universal Beams come in various depths, flange widths, and web thicknesses. Their sizes are typically standardized according to regional or international specifications such as ASTM, BS, or EN. Selecting the right size ensures the beams meet the required load-bearing capacity while minimizing material usage.

Applications of Universal Beams

Universal Beams have a wide range of applications due to their strength, durability, and flexibility. They are a core element in modern infrastructure projects across the world.

Construction Industry

In commercial and residential buildings, Universal Beams are used to support floors, walls, and roofs. They provide structural stability for high-rise towers, bridges, and large halls. Their ability to carry vertical and horizontal loads makes them ideal for foundational frameworks.

Industrial Applications

Factories, warehouses, and plants use Universal Beams to support machinery, mezzanine floors, and industrial platforms. Alloy and stainless-steel UBs are often chosen for environments where durability and resistance to wear are critical.

Infrastructure Projects

Bridges, railways, airports, and tunnels rely heavily on Universal Beams to provide strength and stability. Their high load-bearing capacity and long spans make them essential for public infrastructure.

Residential and Architectural Projects

Universal Beams are also used in residential buildings, providing stability in multi-story houses and modern architectural designs. Stainless steel UBs are sometimes used decoratively due to their sleek appearance and corrosion resistance.

Factors Determining the Quality of Universal Beams

The performance of Universal Beams depends on several quality factors. Engineers and builders must carefully evaluate these before procurement.

Material Composition

The steel grade and chemical composition determine strength, flexibility, and corrosion resistance. High-quality beams are made from certified steel with consistent material composition.

Manufacturing Standards

Hot rolling and welding processes must be performed under strict conditions. Poor manufacturing can result in dimensional inconsistencies or weak joints, compromising safety.

Dimensional Accuracy

Beams must have uniform flange width, web thickness, and straightness. Even small deviations can affect load distribution and structural integrity.

Surface Finish

High-quality Universal Beams should be free from rust, cracks, and warping. Surface coatings such as galvanization or painting enhance durability and protect against environmental damage.

Mechanical Properties

Key properties like tensile strength, yield strength, and elongation determine the beam’s ability to withstand stresses. Reliable suppliers test beams to ensure they meet or exceed mechanical requirements.

Compliance with International Standards

Standards such as ASTM, EN, ISO, or BS provide guidelines for beam dimensions, material composition, and mechanical performance. Beams that comply with these standards offer assurance of reliability and safety.

Testing and Quality Assurance

Rigorous testing, including ultrasonic inspection and load testing, ensures that beams are free from defects and suitable for structural applications. Certified manufacturers provide quality assurance reports for every batch.

Advantages of Using High-Quality Universal Beams

- Strength and Stability: Capable of carrying heavy loads and providing long-term stability.

- Versatility: Suitable for diverse applications across industries.

- Durability: Resistant to wear, corrosion, and environmental stress.

- Cost-Effectiveness: Efficient load distribution reduces the amount of material needed.

- Safety Assurance: Compliance with standards ensures safe and reliable performance.

Selecting the Right Universal Beams

Choosing the right Universal Beams involves evaluating the following factors:

- Project type and load requirements

- Environmental conditions (e.g., exposure to moisture or chemicals)

- Beam size and dimensions as per design specifications

- Quality certifications from the manufacturer

- Long-term cost-effectiveness and maintenance requirements

Working with trusted suppliers ensures timely delivery, compliance with standards, and access to technical expertise.

Conclusion

Universal Beams are the backbone of modern construction and industrial projects. Their unique design, strength, and versatility make them indispensable for applications ranging from buildings and bridges to machinery and infrastructure. However, their performance depends greatly on material quality, manufacturing standards, and compliance with industry regulations.

By prioritizing quality, engineers and project managers can ensure safety, reliability, and long-term efficiency in their structures. Investing in high-quality Universal Beams from certified suppliers is not just a construction decision—it is a commitment to durability, performance, and success.