Types of Printing on Shirts: A Guide to Shirt Printing Methods

T-shirt printing has become one of the most popular forms of personal expression and business branding in the modern fashion world. From startup apparel brands to promotional merchandise and custom gifts, printed shirts are everywhere. But behind every creative design on a shirt lies a printing technique that brings it to life. Each method offers its own set of advantages depending on your needs, such as quantity, material, durability, and cost.

In this article, we’ll explore the most common types of printing on shirts, their pros and cons, and which method works best for different applications.

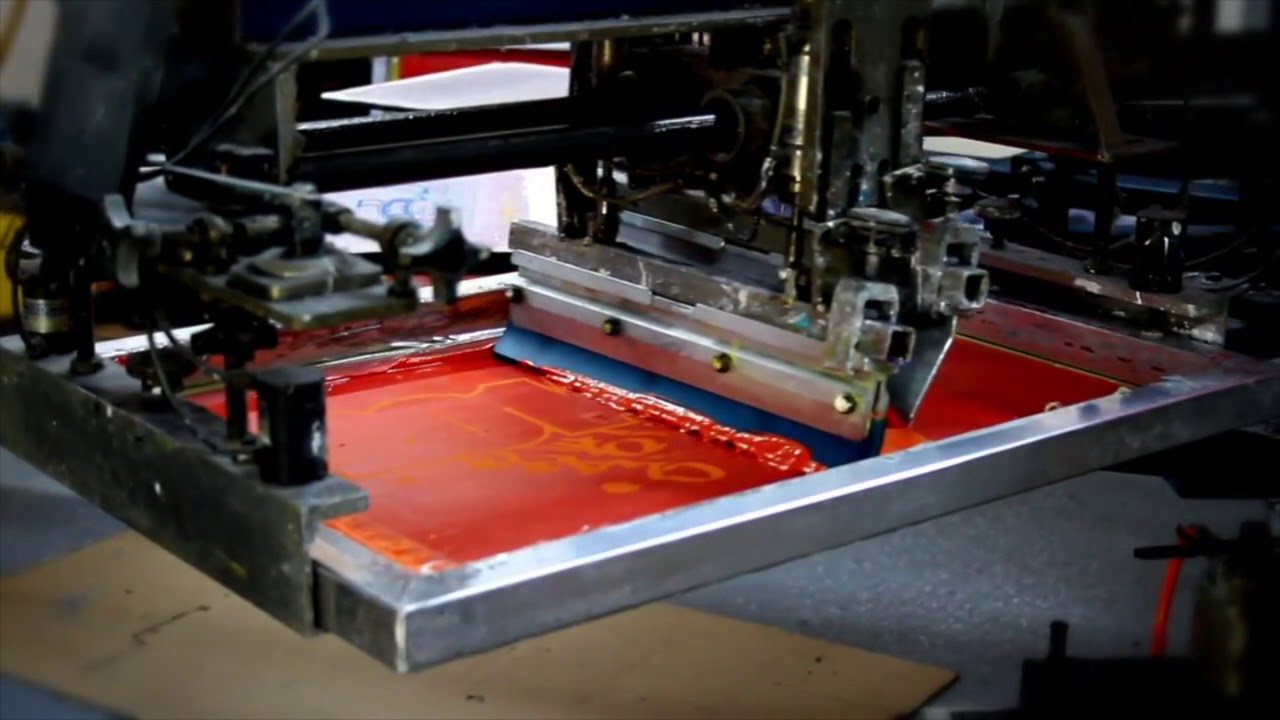

1. Screen Printing (Silkscreen Printing)

Overview:

Screen printing is one of the oldest and most widely used methods for printing on shirts. It involves creating a stencil (or screen) for each color in the design and using ink to transfer the image onto the shirt.

Best for:

- Bulk orders

- Simple designs with limited colors

- Cotton and cotton-blend shirts

Pros:

- Cost-effective for large quantities

- Produces vibrant, durable prints

- Works well on dark and light fabrics

Cons:

- Not ideal for complex or multi-colored designs

- Setup time is longer

- Less efficient for small orders

2. Direct to Garment (DTG) Printing

Overview:

DTG is a modern printing method that uses an inkjet printer to apply water-based inks directly onto the fabric. It works just like a home printer, but for shirts.

Best for:

- Small orders

- Full-color, detailed designs

- Custom one-off shirts

Pros:

- Great for complex, multi-color images

- No setup fees

- Soft finish, no heavy ink layer

Cons:

- Slower than screen printing for large runs

- Works best on 100% cotton

- Less durable than screen prints in some cases

3. Heat Transfer Printing

Overview:

This method involves printing the design on a special transfer paper and then applying it to the shirt using heat and pressure (usually with a heat press).

Best for:

- Small batches or one-off custom prints

- Photographic images

- DIY or home-based projects

Pros:

- Easy to apply at home

- Sharp, detailed prints

- Good for complex and colorful images

Cons:

- May peel or crack over time

- Doesn’t last as long as DTG or screen prints

- Transfer paper can feel stiff on the shirt

4. Sublimation Printing

Overview:

Sublimation printing turns solid dye into gas without passing through the liquid stage. The dye is infused into the fabric, resulting in vibrant, permanent colors.

Best for:

- Polyester or poly-blend fabrics

- All-over prints

- Sportswear and activewear

Pros:

- Extremely durable and vibrant

- Won’t crack, peel, or fade

- Feels soft to the touch

Cons:

- Only works on light-colored, polyester materials

- Not suitable for cotton shirts

- Requires special printers and inks

5. Vinyl Cutting (Heat Transfer Vinyl – HTV)

Overview:

This technique uses a machine to cut designs out of colored vinyl sheets, which are then heat-pressed onto the shirt.

Best for:

- Simple text or logos

- Sports jerseys and team wear

- Durable designs with bold colors

Pros:

- Crisp, clean lines

- Very durable

- Great for names and numbers on sports gear

Cons:

- Not ideal for complex or detailed images

- Can feel thick on the shirt

- Not suitable for large full-color designs

6. Discharge Printing

Overview:

Discharge printing removes the dye from the fabric using a chemical agent and replaces it with a new color, giving a soft, vintage look.

Best for:

- Soft, worn-in look on dark-colored shirts

- Cotton garments

Pros:

- Soft finish

- Creates vibrant prints on dark shirts

- No thick ink layer

Cons:

- Requires precise knowledge of chemistry

- Limited color range

- Works best only on 100% cotton

Choosing the Right Method

Here’s a quick breakdown to help you choose the best shirt printing method:

| Printing Method | Best For | Quantity | Cost (Per Unit) | Durability |

|---|---|---|---|---|

| Screen Printing | Bulk orders, simple designs | High | Low | Very High |

| DTG Printing | Full-color small orders | Low | Moderate | Moderate |

| Heat Transfer | Photos, DIY projects | Low | Low | Low |

| Sublimation Printing | Polyester sportswear | Medium | Moderate | Very High |

| Vinyl Printing | Text/logos on uniforms | Medium | Moderate | High |

| Discharge Printing | Vintage-style designs | Medium | High | High |

Conclusion

With so many types of printing on shirts, the best method depends entirely on your goals. Screen printing is ideal for bulk and bold designs, DTG excels in one-off and photo prints, while sublimation offers unmatched vibrancy for polyester. Whether you’re starting a t-shirt business, customizing apparel for your brand, or creating gifts, knowing the right printing technique can make all the difference in quality, cost, and customer satisfaction.