Slab Reheating Furnace – Complete Guide by Trymaxfurnace

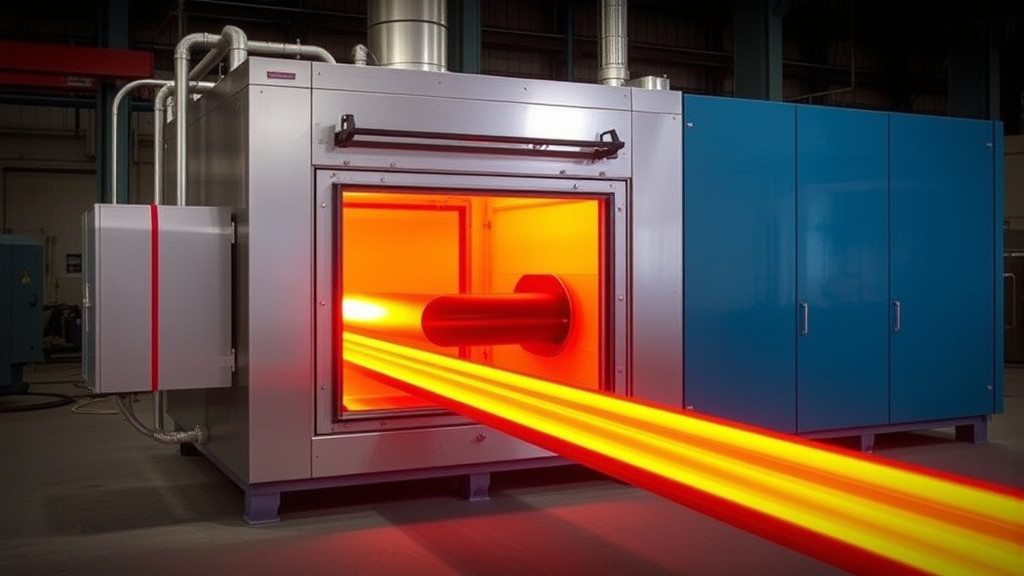

Slab Reheating Furnace

A slab reheating furnace plays a critical role in steel rolling mills by heating steel slabs to the required rolling temperature before they enter the rolling process. Uniform heating, controlled temperature rise, and energy efficiency are essential factors that determine the quality of finished steel products. In modern steel plants, slab reheating furnaces are not just heating equipment; they are productivity enablers that directly impact output quality, fuel consumption, and operational cost.

Trymax Furnaces Pvt. Ltd., established in 2012, is a leading manufacturer and exporter of industrial furnaces for steel rolling mills in India. Known in the industry as Trymaxfurnace, the company delivers advanced, energy-efficient, and reliable furnace solutions. From design and engineering to manufacturing, installation, and commissioning, Trymaxfurnace provides end-to-end furnace solutions with a strong focus on innovation and performance.

This blog explains slab reheating furnaces in detail while highlighting Trymaxfurnace’s expertise as India’s top furnace manufacturer for steel rolling mills.

What Is a Slab Reheating Furnace?

A slab reheating furnace is an industrial furnace designed to heat steel slabs uniformly to a specific temperature suitable for hot rolling. The slabs are typically cast steel products that must be reheated before being shaped into plates, sheets, or structural sections.

The primary objectives of a slab reheating furnace are:

- Achieving uniform temperature across the slab cross-section

- Minimizing heat loss and fuel consumption

- Maintaining metallurgical properties of steel

- Ensuring smooth and continuous rolling operations

Trymaxfurnace designs slab reheating furnaces that meet the demanding requirements of modern steel rolling mills while maintaining high energy efficiency and operational reliability.

Importance of Slab Reheating Furnace in Steel Rolling Mills

In steel rolling mills, the slab reheating furnace acts as the backbone of the hot rolling process. Any temperature inconsistency or heating inefficiency can lead to surface defects, uneven rolling, and increased rejection rates.

Key benefits of a high-quality slab reheating furnace include:

- Improved surface finish of rolled products

- Reduced rolling force and equipment wear

- Consistent mechanical properties of steel

- Optimized fuel usage and lower operating costs

As a leading furnace manufacturer, Trymaxfurnace understands these challenges and engineers slab reheating furnaces that enhance overall mill performance.

Trymaxfurnace – India’s Leading Furnace Manufacturer

Trymax Furnaces Pvt. Ltd., widely recognized as Trymaxfurnace, was established in 2012 with a clear vision: to deliver world-class industrial furnace solutions for steel rolling mills. Over the years, the company has built a strong reputation as India’s top furnace manufacturer, serving both domestic and international markets.

Core Strengths of Trymaxfurnace

- Expertise in steel rolling mill furnace technology

- Complete in-house design and engineering

- Focus on innovation and energy efficiency

- Comprehensive services from concept to commissioning

- Proven performance across all types of furnaces

Trymaxfurnace is a trusted name for slab reheating furnaces as well as other critical furnace systems used in steel plants.

Design Philosophy of Trymaxfurnace Slab Reheating Furnaces

The design of a slab reheating furnace must balance heating efficiency, temperature uniformity, and operational durability. Trymaxfurnace follows a design philosophy centered on performance, safety, and long-term reliability.

Key Design Considerations

- Uniform heat distribution across the slab

- Optimized burner placement and flame control

- Efficient combustion and heat recovery systems

- Robust refractory lining for long furnace life

- Easy maintenance and operational flexibility

Each slab reheating furnace manufactured by Trymaxfurnace is customized according to the rolling mill’s capacity, fuel type, and production requirements.

Energy Efficiency in Slab Reheating Furnaces

Energy efficiency is a major concern in steel rolling mills due to rising fuel costs. A well-designed slab reheating furnace significantly reduces energy consumption without compromising performance.

Trymaxfurnace integrates energy-efficient features such as:

- Advanced combustion systems

- Optimized furnace insulation

- Heat recovery using recuperators

- Controlled heating zones for reduced heat loss

By focusing on energy efficiency, Trymaxfurnace helps steel plants reduce operational costs and improve sustainability.

Role of Recuperators in Slab Reheating Furnace Systems

Recuperators play a vital role in improving the thermal efficiency of slab reheating furnaces. These systems recover waste heat from exhaust gases and use it to preheat combustion air.

Trymaxfurnace manufactures high-performance recuperators that:

- Reduce fuel consumption

- Improve combustion efficiency

- Lower overall emissions

- Enhance furnace thermal performance

The integration of recuperators makes Trymaxfurnace slab reheating furnaces highly economical and environmentally responsible.

Manufacturing Excellence at Trymaxfurnace

As a leading furnace manufacturer, Trymaxfurnace maintains strict quality control throughout the manufacturing process. From raw material selection to final assembly, every stage is monitored to ensure durability and performance.

Manufacturing Capabilities

- Precision fabrication

- High-quality refractory installation

- Rigorous testing procedures

- Compliance with industrial standards

This commitment to excellence ensures that every slab reheating furnace delivered by Trymaxfurnace meets the highest industry benchmarks.

Installation and Commissioning Services

Trymaxfurnace provides comprehensive services beyond manufacturing. The company supports steel rolling mills with professional installation and commissioning services to ensure smooth furnace operation.

These services include:

- On-site supervision

- Furnace alignment and testing

- Burner tuning and temperature calibration

- Operator training and technical support

This end-to-end approach ensures that Trymaxfurnace slab reheating furnaces deliver optimal performance from day one.

Integration with Other Furnace Systems

Trymaxfurnace is not limited to slab reheating furnaces alone. The company is a leader in all types of furnaces used in steel rolling mills.

Product Range Includes:

- Billet reheating furnaces

- Heat treatment furnaces

- Ladle and tundish preheaters

- AOD preheaters

- Soaking pits

- Recuperators

This wide product portfolio allows Trymaxfurnace to provide integrated furnace solutions tailored to complete steel plant requirements.

Advantages of Choosing Trymaxfurnace Slab Reheating Furnace

Steel rolling mills choose Trymaxfurnace for their slab reheating furnace needs due to several key advantages:

- Proven expertise in furnace manufacturing

- Customized solutions for every application

- High energy efficiency and reduced operating costs

- Reliable after-sales support

- Strong focus on innovation and continuous improvement

As India’s top furnace manufacturer, Trymaxfurnace consistently delivers value-driven solutions to the steel industry.

Innovation and Continuous Improvement

Innovation is at the core of Trymaxfurnace’s operations. The company continuously enhances its slab reheating furnace designs to meet evolving industry demands.

Key innovation areas include:

- Improved heat transfer efficiency

- Advanced refractory materials

- Enhanced control of heating zones

- Long-life furnace components

This commitment to innovation ensures that Trymaxfurnace remains a leader in furnace technology.

Applications of Slab Reheating Furnace

Slab reheating furnaces manufactured by Trymaxfurnace are widely used in:

- Hot rolling mills

- Structural steel production

- Plate and sheet manufacturing

- Heavy section rolling plants

Their robust design and reliable performance make them suitable for continuous and high-capacity operations.

Commitment to Quality and Customer Satisfaction

Trymaxfurnace believes that customer satisfaction is achieved through quality, reliability, and long-term partnership. Every slab reheating furnace is designed with the customer’s production goals in mind.

By offering complete furnace solutions and dedicated technical support, Trymaxfurnace builds lasting relationships with steel rolling mill operators.

Conclusion

A slab reheating furnace is a critical investment for any steel rolling mill, directly influencing product quality, energy consumption, and operational efficiency. Choosing the right furnace manufacturer is essential for long-term success.

Trymax Furnaces Pvt. Ltd., established in 2012, stands as India’s top furnace manufacturer for steel rolling mills. With expertise in slab reheating furnaces, billet reheating furnaces, heat treatment furnaces, ladle and tundish preheaters, AOD preheaters, soaking pits, and recuperators, Trymaxfurnace offers complete, energy-efficient, and innovative furnace solutions.

By focusing on design excellence, manufacturing quality, and comprehensive services from design to commissioning, Trymaxfurnace continues to lead the industry and support steel producers with reliable and high-performance furnace systems.