Revolutionizing Metal Maintenance: How Laser Cleaning Metal is Changing the Game

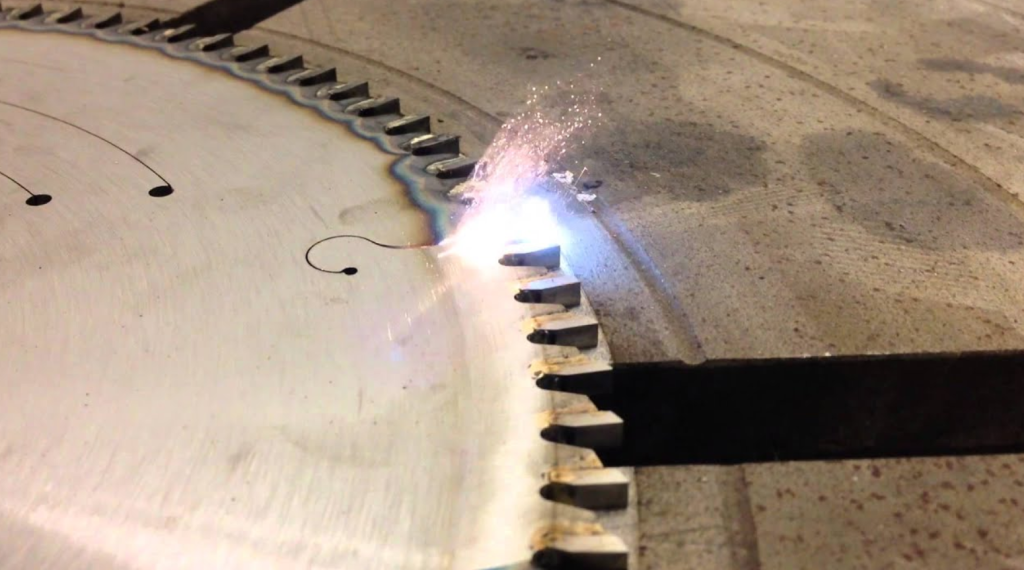

In modern industrial processes, maintaining the quality and longevity of metal surfaces is a critical challenge. Traditional cleaning methods like sandblasting, chemical treatments, or abrasive techniques often cause surface damage, leave residues, or require significant downtime. This is where laser cleaning metal technology emerges as a groundbreaking solution, offering precision, efficiency, and eco-friendly results.

Mart Laser has positioned itself at the forefront of this innovation, providing advanced laser cleaning systems tailored for various industrial applications. Unlike conventional methods, laser cleaning employs highly focused light beams to remove contaminants, rust, paint, and oxidation from metal surfaces without physical contact. This method preserves the integrity of the underlying material while delivering a consistently clean surface ready for further processing or coating.

One of the most significant advantages of laser cleaning is its versatility. Whether it’s steel, aluminum, copper, or other alloys, laser systems can handle different types of metals and contaminants. This flexibility allows industries ranging from automotive and aerospace to shipbuilding and electronics to adopt the technology seamlessly. Mart Laser’s equipment comes with adjustable power settings, making it suitable for delicate surfaces as well as heavily corroded materials.

Environmental and safety considerations are also paramount in modern industrial operations. Traditional cleaning methods often rely on chemicals, solvents, or abrasive powders that can harm workers and the environment. Laser cleaning, on the other hand, eliminates the need for toxic chemicals and minimizes waste, making it a cleaner, safer, and more sustainable option. Companies choosing Mart Laser not only improve operational efficiency but also align with environmental standards and workplace safety protocols.

Another key factor that makes laser cleaning metal a game-changer is speed and precision. Manual cleaning methods are labor-intensive and often inconsistent, but laser cleaning provides uniform results with minimal operator intervention. Mart Laser systems are equipped with advanced software and automation features, enabling precise control over the cleaning process. This reduces downtime, increases productivity, and ensures that metal components meet exacting standards before further fabrication or assembly.

Investing in laser cleaning technology from Mart Laser also translates into long-term cost savings. Although the initial investment may be higher compared to conventional methods, the reduction in labor, chemicals, and potential rework can quickly offset costs. Furthermore, the non-abrasive nature of laser cleaning extends the life of metal components, reducing replacement frequency and improving overall equipment reliability.

In conclusion, laser cleaning metal represents a revolutionary step forward for industries seeking precision, efficiency, and sustainability. Mart Laser’s innovative solutions combine cutting-edge technology with practical usability, enabling businesses to optimize their metal cleaning processes without compromising safety or quality. For companies looking to future-proof their operations, investing in Mart Laser’s laser cleaning systems is a strategic move toward cleaner, faster, and more reliable metal maintenance.