Metal Enclosure Design Trends Transforming Industrial Spaces

Industrial design is rapidly evolving, and metal enclosures are at the center of this transformation. From modern factories to high-tech data centers, the way enclosures are built and integrated into facilities is changing the landscape of industrial spaces. As industries demand more from their infrastructure—efficiency, durability, and adaptability—designers and engineers are rethinking how metal enclosures contribute not only to function but also to form.

Sustainable and Energy-Efficient Designs

Sustainability is driving change across every industry, and enclosure design is no exception. Manufacturers are increasingly focusing on eco-friendly materials and production methods to reduce carbon footprints. Modern enclosures now utilize recyclable metals such as aluminum and steel, which offer both durability and environmental benefits. Energy efficiency is also a major consideration. Designers are integrating passive cooling systems and advanced ventilation patterns that minimize the need for mechanical cooling, saving energy and extending equipment life. These green innovations help industrial facilities meet stricter environmental standards while reducing operational costs over time.

Integration of Smart Technologies

In today’s connected world, a metal enclosure is more than just a protective box—it’s an intelligent part of the industrial ecosystem. With the rise of the Industrial Internet of Things (IIoT), enclosures are now equipped with sensors, smart locks, and monitoring systems. These technologies allow real-time tracking of internal temperature, humidity, and equipment performance. Smart enclosures also enhance security by detecting unauthorized access or environmental changes that could affect operations. This digital integration ensures that facilities can operate more safely, efficiently, and predictably, making technology-enabled enclosures a defining trend in modern industrial design.

Modular and Flexible Configurations

The industrial sector thrives on adaptability. As production needs shift and equipment evolves, modular metal enclosure systems have become a game-changer. Instead of traditional fixed structures, modular enclosures allow easy reconfiguration, expansion, and maintenance. This flexibility helps industries reduce downtime and respond quickly to changing requirements. Modular designs are especially popular in manufacturing, renewable energy, and telecom sectors, where scalability and rapid deployment are critical. These enclosures not only streamline workflows but also optimize space utilization, a key consideration in crowded or evolving industrial environments.

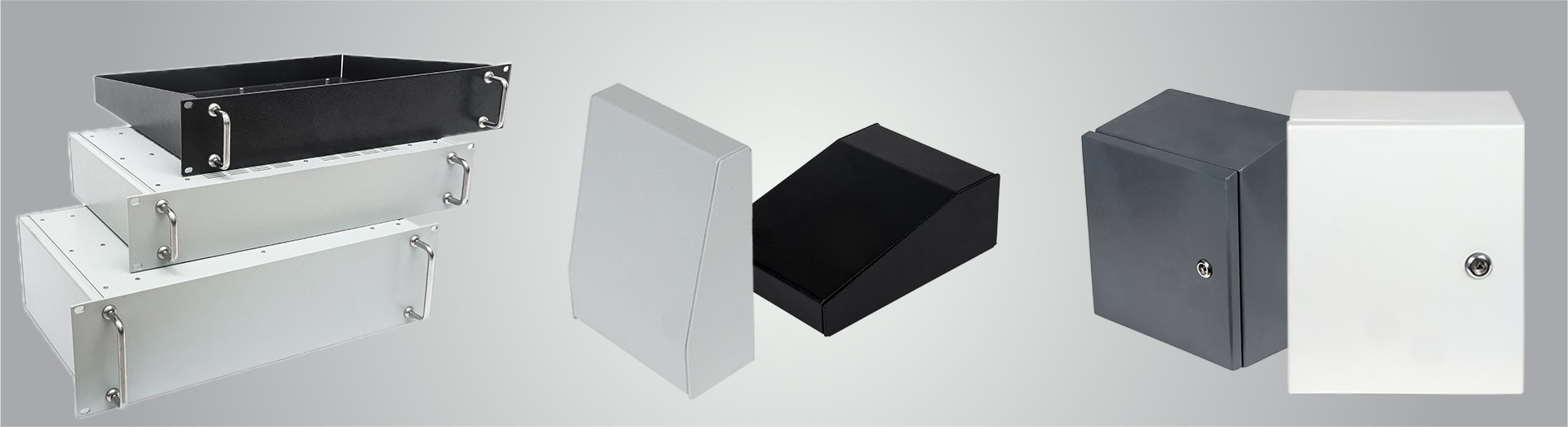

Enhanced Aesthetic Appeal and Ergonomics

Industrial design is no longer just about practicality—it’s also about presentation. Modern enclosures are being designed with clean lines, smooth finishes, and sleek aesthetics that fit seamlessly into advanced industrial spaces. Powder-coated surfaces, corrosion-resistant finishes, and color customization options make them both attractive and durable. Ergonomics also play a growing role. Easy-access panels, better handle placements, and intuitive layouts simplify user interaction and maintenance. This human-centric approach to design enhances efficiency and safety, ensuring that the enclosures serve both visual and functional purposes in a professional setting.

Improved Safety and Compliance Standards

Safety remains a top priority across all industrial sectors. New trends in enclosure design emphasize advanced protection against environmental hazards, electrical faults, and physical impacts. Enclosures are now being built to meet stricter international standards for ingress protection (IP), fire resistance, and electromagnetic shielding. High-quality seals, reinforced joints, and advanced grounding systems ensure reliable operation even in the harshest environments. By combining durability with compliance, these designs not only protect sensitive equipment but also safeguard workers and the surrounding infrastructure.

Customization and Industry-Specific Solutions

No two industries have identical needs, and this realization has spurred a shift toward customized enclosure solutions. Designers now collaborate closely with engineers and end-users to develop enclosures that fit specific applications—whether it’s housing delicate electronics, heavy machinery, or automation systems. Custom features such as integrated cable management, internal lighting, and specialized coatings provide added functionality. The result is a more efficient, purpose-built enclosure that aligns perfectly with each facility’s technical and environmental demands.

Conclusion

The evolution of metal enclosure design is reshaping industrial spaces in remarkable ways. With trends focusing on sustainability, smart technology, flexibility, and enhanced safety, today’s enclosures do far more than protect—they contribute to productivity, energy efficiency, and overall operational excellence. As industries continue to modernize, the fusion of intelligent design and durable engineering ensures that metal enclosures will remain a cornerstone of innovation across industrial environments. The future of enclosure design lies in creating structures that are not just strong and secure, but also smart, sustainable, and seamlessly integrated into the industrial spaces they protect.