How LiDAR Scan to BIM Improves As-Built Model Accuracy

As-built models act as the reference point for renovation design, system upgrades, and long-term building operations. Many existing buildings rely on drawings that no longer match site reality. During construction, wall positions adjust, slab elevations change, and service routes shift to resolve field constraints. These changes often remain undocumented. Over time, the gap between recorded drawings and actual conditions increases. When teams depend on assumed dimensions, errors appear during coordination, quantity checks, and installation planning. Inaccurate as-built data leads to redesign cycles, site corrections, and delays. Reliable as-built model accuracy depends on capturing verified geometry rather than inferred measurements.

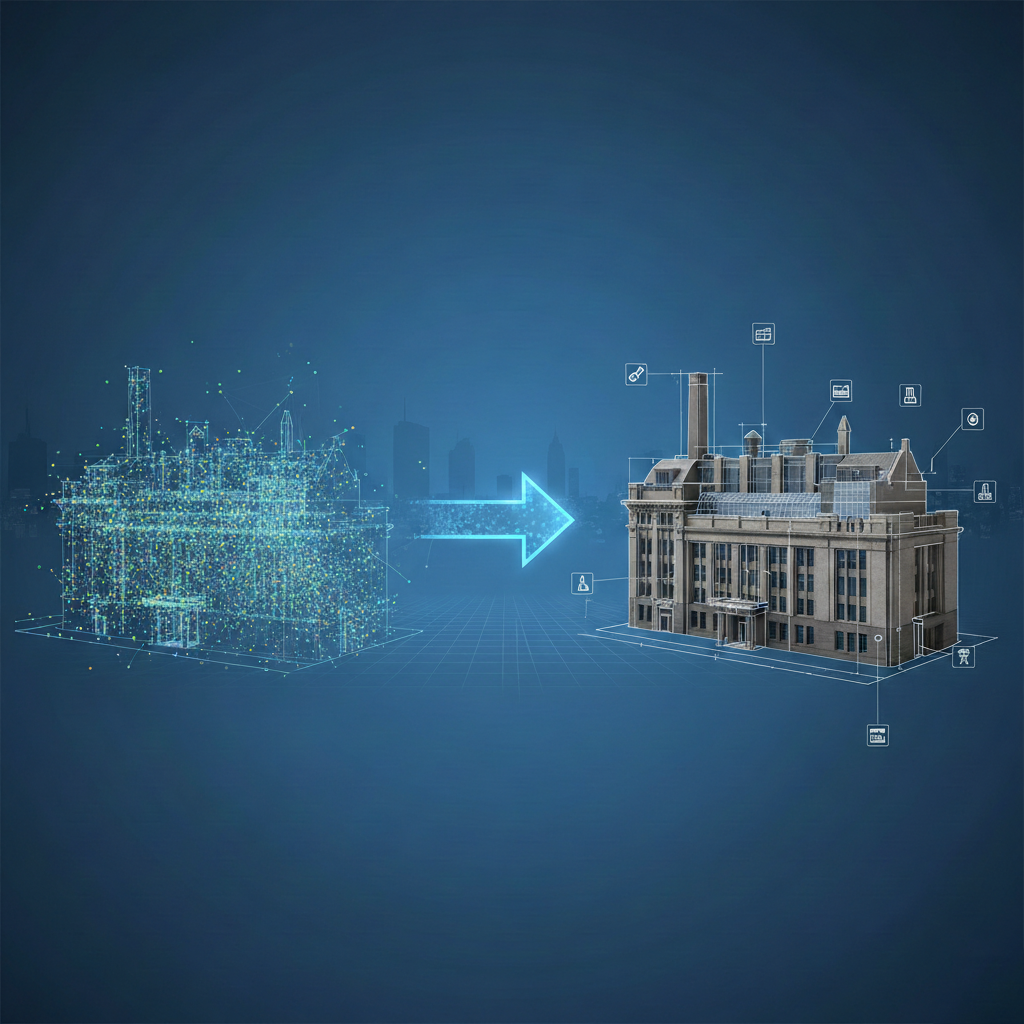

LiDAR Scan to BIM addresses this accuracy gap by recording existing conditions directly from the site. LiDAR scanners emit laser pulses that measure distances based on time-of-flight calculation. Millions of spatial points are captured across floors, walls, structures, and services. This point cloud represents true geometry, elevation, and alignment. Scan to BIM converts the point cloud into intelligent BIM elements with measured dimensions for as-built BIM modeling. The resulting model reflects actual site conditions, not design assumptions. This data-driven approach improves confidence during renovation planning, coordination tasks, and facility management activities.

Why Traditional As-Built Surveys Lack Accuracy?

Traditional as-built surveys rely on manual measurement methods and individual interpretation. Tools such as tape measures, laser distance meters, and total stations collect data at selected points rather than across full surfaces. Surveyors choose reference locations based on accessibility, which leaves gaps in coverage. Irregular wall faces, floor level variations, and minor offsets often go unrecorded. In congested spaces, measurements are taken at limited angles, increasing deviation. The resulting drawings represent averaged or inferred dimensions instead of actual site geometry captured in full.

Site conditions also change throughout the construction and fit-out stages. Structural openings shift, service routes adjust, and installations move to resolve clashes. These changes are rarely documented in real time. Manual surveys conducted after completion capture only visible elements and ignore concealed services. Recording, transcription, and drafting introduce additional error layers. Dense MEP zones and non-orthogonal layouts are difficult to measure accurately using manual methods. These factors reduce the reliability of traditional as-built surveys and increase downstream coordination and construction risk.

How LiDAR Scan to BIM Improves Dimensional Accuracy?

Surface-based measurement instead of point-to-point sampling

Traditional surveys record distances between selected reference points. LiDAR scanner captures continuous surface geometry. Every wall, slab, and ceiling plane is recorded as thousands of spatial points. Dimensional values are derived from surface behavior rather than isolated measurements. This exposes bowing, offsets, and non-parallel conditions that manual methods average out. The BIM model reflects actual constructed geometry, not idealized dimensions.

True distance calculation using time-of-flight data

LiDAR scanners calculate distance by measuring the return time of emitted laser pulses. Each point stores XYZ coordinates generated directly from this calculation. No scaling, interpolation, or visual estimation is involved. This removes cumulative rounding errors common in manual workflows. Dimensional accuracy is maintained uniformly across small rooms and large floor plates because every measurement originates from the same physical process.

Plane fitting based on statistical point distribution

Walls and slabs are created by fitting planes through clusters of scan points in 3D scan to BIM modeling. These planes represent the dominant constructed surface, not assumed straight lines. Minor construction tolerances remain visible. This method captures real wall orientation and slab slope. Dimensional data reflects construction reality rather than design intent.

Vertical accuracy through full-height data capture

Manual surveys often measure vertical dimensions at limited locations. LiDAR captures vertical data across full wall and column heights. This reveals plumb deviation, tapering, and level variation. Floor-to-floor heights, beam soffits, and ceiling offsets are extracted directly from scan data. Vertical dimensions in the BIM model match site conditions without averaging or adjustment.

Coordinate-controlled alignment across scans

Multiple LiDAR scans are registered into a single coordinate system using targets or cloud-to-cloud registration. This locks all dimensions to a consistent spatial reference. Unlike manual surveys that reset references room by room, Scan to Revit maintains alignment across floors and zones. Dimensional drift is eliminated, which is critical for large buildings and phased renovation projects.

Clearance verification in dense service zones

LiDAR captures the exact spatial envelope occupied by ducts, pipes, and cable trays. Distances between services and surrounding structures are measured directly from scan data. BIM models generated from this data show real clearance conditions. This avoids relying on nominal sizes or outdated drawings, which frequently cause conflicts during retrofit installation.

Opening and penetration position accuracy

Door openings, shafts, and floor penetrations often shift during construction. LiDAR scans capture their final position relative to the structure and finishes. 3D BIM modeling traces these elements from the point cloud, preserving true offsets and sizes. This improves dimensional accuracy for prefabrication, equipment placement, and firestopping coordination.

Detection of cumulative construction tolerances

Small deviations accumulate across slabs, walls, and structural grids. Manual surveys rarely capture this accumulation. LiDAR data reveals how tolerances stack across a building. BIM models based on scan data reflect these compounded shifts. This improves dimensional reliability when aligning new construction with existing conditions.

Quantifiable tolerance checking during modeling

Point cloud to BIM workflows allow dimensional comparison between BIM elements and point cloud data. Deviations can be measured numerically rather than visually. Model elements outside acceptable tolerance ranges are corrected during modeling. This produces as-built models with documented dimensional accuracy suitable for renovation design, coordination, and asset planning.

Future Improvements in LiDAR-Based As-Built Accuracy

Future accuracy gains are coming from how scan data is generated and registered rather than from higher point counts alone. New scanners use improved beam stability and multi-return processing to reduce edge distortion on corners, curved surfaces, and thin elements. Better control of scan overlap improves registration accuracy, reducing cumulative alignment error across floors and long corridors. These changes directly affect dimensional reliability in large buildings where small misalignments multiply.

Accuracy improvements are also occurring at the model comparison stage. Automated deviation tools now quantify the distance between BIM geometry and point cloud data instead of relying on visual checks. Object recognition systems use geometric behavior rather than color data, improving consistency across different lighting conditions. Periodic rescanning linked to operational models allows dimensional changes to be tracked over time, supporting accurate long-term as-built records.

Conclusion

LiDAR Scan to BIM provides a measurable approach to as-built model accuracy by capturing existing conditions directly from the site. Laser-based scanning records true geometry, alignment, and dimensional variation that manual surveys often miss. BIM models created from point cloud data reflect constructed reality rather than assumed values. This reduces dimensional conflicts during renovation, retrofit, and system upgrades. Accurate as-built models support coordination, planning, and asset documentation. For complex renovation and facility projects, Lidar Scan to BIM Services in USA are widely used to maintain reliable dimensional accuracy across the building lifecycle.