How Do MEP BIM Services Enable Modern Digital Building Models?

Digital building models represent more than three-dimensional geometry. They describe how air moves through occupied spaces, how power reaches critical equipment, how water flows across vertical and horizontal zones, and how safety systems respond during emergencies. These functions originate from mechanical, electrical, plumbing, and fire protection systems. Without accurate system modeling, digital buildings fail to reflect real operational behavior. MEP BIM Services convert engineering designs into system-based digital structures that define routing logic, equipment relationships, and spatial dependencies. This modeling approach replaces assumption-driven layouts with verified system placement that aligns with structural limits and architectural intent.

Modern digital building workflows demand precise system intelligence rather than visual coordination alone. MEP BIM Services embed technical parameters such as airflow capacity, electrical load distribution, pipe sizing, and system clearances directly into model elements. These parameters allow building models to support coordination reviews, constructability evaluation, and performance planning without revisiting disconnected documentation. The model evolves into a central source of technical information that supports consistent decision-making across project stages. By maintaining system accuracy and data continuity, projects achieve higher reliability during construction and long-term operation.

Why Do Modern Digital Building Models Depend on MEP BIM Services?

Modern digital building models depend on MEP 3D modeling Services because system behavior defines how buildings function in real conditions. Mechanical systems control thermal comfort and ventilation performance. Electrical networks govern power distribution and equipment reliability. Plumbing systems manage water supply and waste flow across building levels. Fire safety support life safety planning and compliance. MEP System BIM Services translate these engineering requirements into coordinated digital models that reflect spatial constraints and operational logic. This system-based modeling approach allows coordinated MEP to support technical validation, coordination review, and informed decision-making throughout design, construction, and building use.”

How Do MEP BIM Services Digitally Represent Mechanical, Electrical, Plumbing, and Fire Protection Systems?

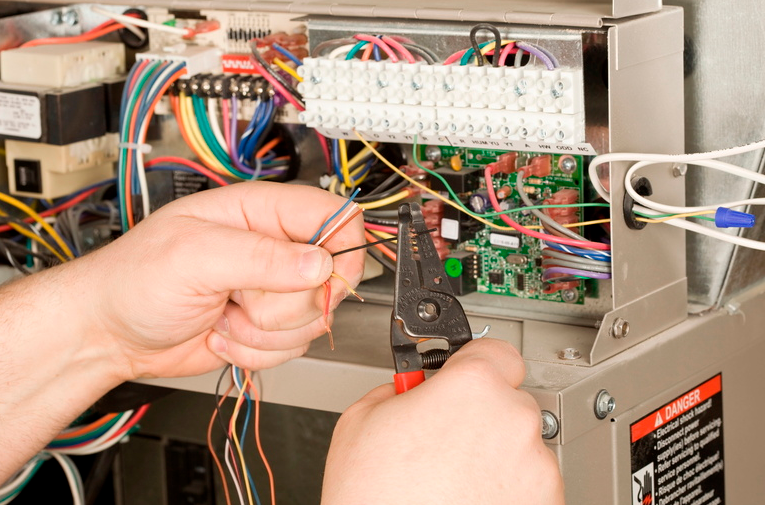

Digital MEP services convert engineering designs into coordinated digital systems within a single building model. Each system receives defined geometry, routing logic, and technical attributes based on discipline standards. The model reflects real spatial conditions, service zones, and system interfaces.

These coordinated digital models are commonly developed using industry-standard platforms such as Autodesk Revit to ensure modeling accuracy, coordination, and data consistency across disciplines.

Digitally Represent Mechanical Systems

Mechanical BIM modeling translates HVAC system designs into fully parametric digital objects. Air handling units, fan coil units, and chillers carry capacity, airflow, and pressure specifications. Duct networks are modeled with exact cross-sections, slope angles, and elevation offsets. The model captures branch take-offs, tap connections, and transitions between rectangular and round ducts. Spatial clearance around equipment and service zones are explicitly defined. Designers validate airflow paths, pressure drop requirements, and installation sequences. Mechanical controls and sensors are embedded to support commissioning simulations, load balancing, and integration with building automation.

Key Details

- AHUs, FCUs, chillers modeled with flow and pressure data

- Duct networks with precise dimensions, slopes, and offsets

- Branch connections and transitions accurately represented

- Diffusers, grilles, and vents positioned with airflow calculations

- Service clearances and maintenance zones modeled

- Mechanical sensor and control points embedded

Structure Electrical Systems Within Digital Models

Electrical BIM modeling digitizes power distribution, emergency circuits, lighting, and low-voltage systems. Panels, switchboards, and transformers are modeled with voltage, capacity, and fault rating. Cable trays, conduits, and bus ducts follow optimized routing paths avoiding structural interference. Lighting fixtures are positioned with lumens, color temperature, and zoning data. Emergency lighting and backup circuits include redundancy parameters. Circuit breakers, junction boxes, and cable bends are included to reflect real installation constraints. The model supports load calculations, voltage drop analysis, and construction sequencing for multiple floors.

Key Details

- Panels, transformers, switchboards with voltage and capacity data

- Cable trays/conduits routed around structural elements

- Lighting fixtures positioned with lumens, color temperature, and zoning

- Circuit breakers and junction boxes modeled with connection logic

- Redundant emergency circuits included

- Cable bend radius and conduit fill verified

Define Plumbing and Drainage Systems Digitally

Plumbing BIM models define water supply, drainage, and sanitary systems with hydraulic precision. Pipe diameters, flow rates, and slope gradients are encoded for gravity and pressurized. Vertical risers coordinate across multiple floors with offsets from beams and ceilings. Valves, pumps, and tanks carry operational parameters for simulation. Fixture connections include exact inlet/outlet locations. The model enables clash detection with HVAC ducts and electrical conduits, while maintaining accessibility for maintenance. Designers can simulate water pressure, velocity, and potential bottlenecks before installation.

Key Details

- Pipes modeled with exact diameters, material, and pressure ratings

- Slope and elevation adjustments for gravity drainage

- Vertical risers coordinated across floors

- Valves, pumps, and tanks modeled with operational data

- Fixture connections with precise inlet/outlet points

- Clearance zones maintained for maintenance and inspection

Integrate Fire Protection Systems Into Digital Buildings

Fire Safety BIM modeling digitizes sprinkler, fire pumps, standpipes, and control valves with operational logic. Sprinkler head placement follows hazard classification, coverage radius, and spacing criteria. Piping networks account for ceiling obstructions, HVAC ducts, and other MEP services. Pressure and flow parameters are integrated for hydraulic calculations. Fire risers, pumps, and alarm components include access and maintenance zones. The model supports coordination reviews, installation sequencing, and system testing. Integration with digital building models allows verification of regulatory compliance and conflict-free system layouts.

Key Details

- Sprinkler heads placed with coverage radius and hazard class

- Fire piping routed around structural elements and MEP systems

- Hydraulic pressure and flow data integrated

- Fire risers, pumps, and valves modeled with operational parameters

- Access and maintenance zones clearly defined

- Coordination checked with ceilings, ducts, and electrical pathways

Benefits of MEP BIM Services

- Coordinate mechanical, electrical, plumbing, and FP systems within a unified digital model to prevent spatial and operational conflicts.

- Identify and resolve clashes between MEP elements and architectural or structural components, reducing field rework and installation delays.

- Model systems according to installation sequences, including equipment access zones, duct slopes, pipe offsets, and conduit routing for accurate constructability planning.

- Embed parametric data and engineering attributes into MEP components, enabling load calculations, pressure analysis, and system validation during design.

- Support energy performance, HVAC efficiency, and water distribution analysis using accurate, data-rich digital models.

- Provide as-built MEP system information for facility management, including maintenance planning, asset tracking, and lifecycle performance monitoring.

How Do MEP BIM Services Support Construction Building Operations?

BIM-Based MEP Services provide facility managers with precise digital models containing parametric data for every mechanical, electrical, plumbing, and fire protection component. HVAC equipment models include airflow capacity, duct velocity, and maintenance clearances, allowing operators to plan filter replacements, fan balancing, and airflow optimization. Electrical panels, circuit loads, and conduit layouts provide actionable insights for load distribution, breaker testing, and power system adjustments. Plumbing models contain pipe diameters, flow rates, and pump performance data, enabling predictive maintenance, leak detection, and pressure monitoring. Fire Safety integrates sprinkler coverage, riser locations, and valve access zones, supporting inspection schedules, hydraulic testing, and compliance verification. Operators can simulate system adjustments and assess impact before physical intervention, reducing operational risk.

BIM-based digital models also enable integration with building management and digital twins for continuous monitoring. Maintenance schedules, sensor data, and energy consumption metrics can be mapped directly to model components. This allows coordinated planning across multiple MEP systems, tracking of asset lifecycles, and real-time performance analysis. Facility teams gain a single source of verified system information, improving decision-making, reducing unplanned downtime, and supporting long-term operational efficiency.

Conclusion

MEP Design and modeling Services deliver fully coordinated digital representations of mechanical, electrical, plumbing, and fire protection systems, capturing parametric data, system capacities, and spatial relationships. These models allow facility teams to monitor airflow, electrical load distribution, water pressure, and sprinkler coverage with precision. Maintenance tasks, system testing, and energy performance analysis can be executed directly from the model. By linking operational metrics with accurate system geometry, buildings achieve reduced downtime, optimized resource allocation, and improved asset lifecycle management, providing a single source of verified technical information for long-term operational decision-making.