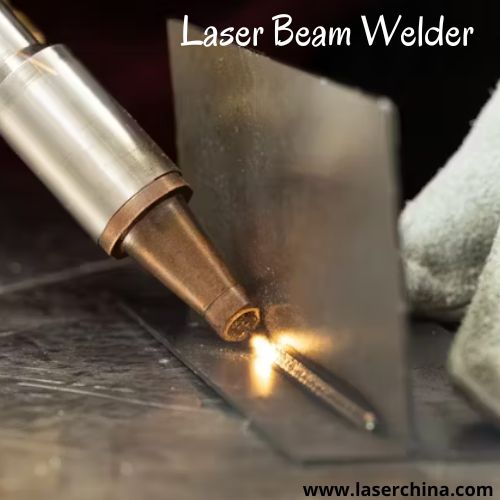

Elevating Manufacturing Efficiency with a Laser Beam Welder

In today’s fast-paced manufacturing world, businesses are constantly searching for smarter, faster, and more precise ways to improve production. One of the technologies transforming industries such as automotive, aerospace, and medical device production is the laser beam welder. Known for its accuracy and efficiency, this welding solution has become a must-have tool for companies striving to stay competitive.

What Makes a Laser Beam Welder Stand Out?

Traditional welding methods often involve high heat, significant material distortion, and longer processing times. In contrast, a laser beam welder uses concentrated light energy to join metals with pinpoint precision. This method offers:

- Minimal heat distortion – ensuring cleaner, stronger welds.

- Faster processing speeds – reducing downtime and improving throughput.

- Versatility across materials – from stainless steel to aluminum and advanced alloys.

With growing demand for high-performance, lightweight components, industries worldwide are leaning toward laser welding technology to meet strict quality standards.

Why Manufacturers Choose LaserChina

When it comes to reliable laser solutions, LaserChina is recognized as a trusted global partner. The company offers cutting-edge laser beam welders and accessories designed to meet the evolving needs of modern manufacturing.

LaserChina stands out for:

- Advanced technology integration – combining automation and AI-driven controls for maximum precision.

- Customizable solutions – tailored equipment to fit unique production requirements.

- Strong global presence – serving clients across multiple industries with high-performance laser systems.

Whether you’re looking to upgrade your production line or integrate a brand-new laser welding system, LaserChina provides the expertise and equipment to drive efficiency.

Current Trends in Laser Welding Technology

Recent developments highlight how laser welding is evolving beyond basic applications:

- Fiber laser systems are gaining popularity due to higher energy efficiency and reduced maintenance.

- Robotic laser welding enables automation in complex production lines, reducing labor costs.

- Smart monitoring systems now allow real-time quality checks, ensuring defect-free welds.

These innovations show why adopting a laser beam welder today is not just a technological upgrade but also a strategic move for long-term growth.

Applications Across Industries

The adaptability of laser beam welders makes them invaluable in various sectors:

- Automotive: Lightweight car components and EV battery packs.

- Medical devices: Precise welds for surgical tools and implants.

- Electronics: Delicate welding for circuit boards and micro-components.

- Aerospace: Strong, reliable welds on critical structural parts.

By delivering consistent results, laser welding ensures that products meet international safety and performance standards.

Final Thoughts

Investing in a laser beam welder is no longer just about improving weld quality—it’s about unlocking new opportunities for innovation and efficiency. With the support of experienced providers like LaserChina, businesses can confidently embrace modern manufacturing challenges while staying ahead of the competition.