Chemical Companies Near Me: Finding the Right Fit: A Guide to Selecting a Nearby Partner

Choosing the right chemical supplier is a critical decision for businesses in manufacturing, pharmaceuticals, food production, and countless other industries. The supplier you choose affects not only the quality of your products but also your compliance, efficiency, and long-term growth. A reliable partner ensures smooth operations, while the wrong choice can result in delays, safety issues, and financial losses.

That’s why many businesses begin their search with Chemical Companies Near Me. Local partnerships provide faster communication, quicker deliveries, and a deeper understanding of regional regulations. But proximity alone is not enough—finding the right fit requires careful evaluation of multiple factors.

Why the Right Chemical Partner Matters

Chemicals are integral to production processes, but they come with complexities. Every industry has strict standards for safety, consistency, and traceability. Suppliers that cannot meet these requirements introduce risk into operations. Beyond supplying materials, a good partner adds value by offering technical expertise, compliance support, and scalable solutions.

The right partner also strengthens competitiveness. Reliable supply chains minimize downtime, while innovative providers can help you adapt to market changes faster. Ultimately, supplier selection is a strategic decision, not just a logistical one.

Key Criteria for Selecting a Chemical Partner

When evaluating potential suppliers, businesses should assess more than pricing. The following criteria determine whether a supplier will be a long-term asset or a short-term liability.

1. Regulatory Compliance and Certifications

Regulatory compliance is non-negotiable in the chemical industry. Look for partners that hold the necessary certifications such as ISO, REACH, or GMP. These demonstrate adherence to quality and safety standards.

Non-compliant suppliers can expose your company to penalties, recalls, and reputational damage. A certified partner provides peace of mind that products meet both local and global requirements.

2. Product Range and Specialization

Suppliers vary in their capabilities. Some offer a broad range of bulk chemicals, while others specialize in niche formulations. Assess whether their product range aligns with your current needs and potential future requirements.

Specialized suppliers often bring technical expertise that helps optimize formulations or identify alternatives, giving you a competitive advantage in product development.

3. Supply Chain Reliability

Even the best chemicals are worthless if they do not arrive on time. Evaluate a supplier’s logistics capabilities, delivery track record, and inventory management. Local suppliers often excel in responsiveness, but reliability must still be confirmed through references and performance history.

Ask about contingency plans in case of transportation delays or raw material shortages. A reliable supplier ensures uninterrupted operations.

4. Quality Assurance Systems

Consistency in chemical quality is essential for maintaining product standards. Reliable partners use rigorous testing and quality control systems to ensure each batch meets specifications.

Request information about their testing methods, certifications, and traceability processes. A transparent supplier will provide detailed documentation that supports your audits and compliance requirements.

5. Safety and Environmental Responsibility

Chemicals carry inherent risks, making safety practices critical. Suppliers should have robust safety protocols for storage, handling, and transportation. In addition, companies with strong environmental policies demonstrate responsibility and alignment with global sustainability goals.

Partnering with an environmentally conscious supplier strengthens your own brand reputation and reduces risk exposure in an era of heightened regulatory scrutiny.

6. Technical Support and Expertise

The best suppliers offer more than raw materials—they provide guidance. Technical support teams can help troubleshoot issues, improve efficiency, or develop new solutions. This is especially important for industries where formulations are complex or highly regulated.

A supplier with strong technical expertise becomes an extension of your team, contributing directly to product success.

7. Pricing Transparency and Flexibility

While cost matters, the lowest price is rarely the best long-term option. Transparent pricing models and flexible contracts ensure a balanced relationship. Suppliers should be willing to explain cost structures and accommodate changing order volumes.

Flexible arrangements allow you to adjust quickly to shifts in demand without being locked into unfavorable terms.

Benefits of Partnering Locally

Working with nearby suppliers offers distinct advantages:

- Faster Delivery

Reduced shipping distances shorten lead times, allowing businesses to respond quickly to market demands. - Lower Transportation Costs

Proximity reduces logistics expenses, particularly for heavy or hazardous materials. - Better Communication

Local partners are often more accessible for site visits, audits, or troubleshooting. - Regional Knowledge

Familiarity with local regulations and markets ensures smoother compliance and alignment with industry practices.

While global suppliers may offer scale, local companies often provide the responsiveness and flexibility that smaller businesses require.

Common Mistakes to Avoid

When selecting a partner, businesses often make missteps that undermine long-term success:

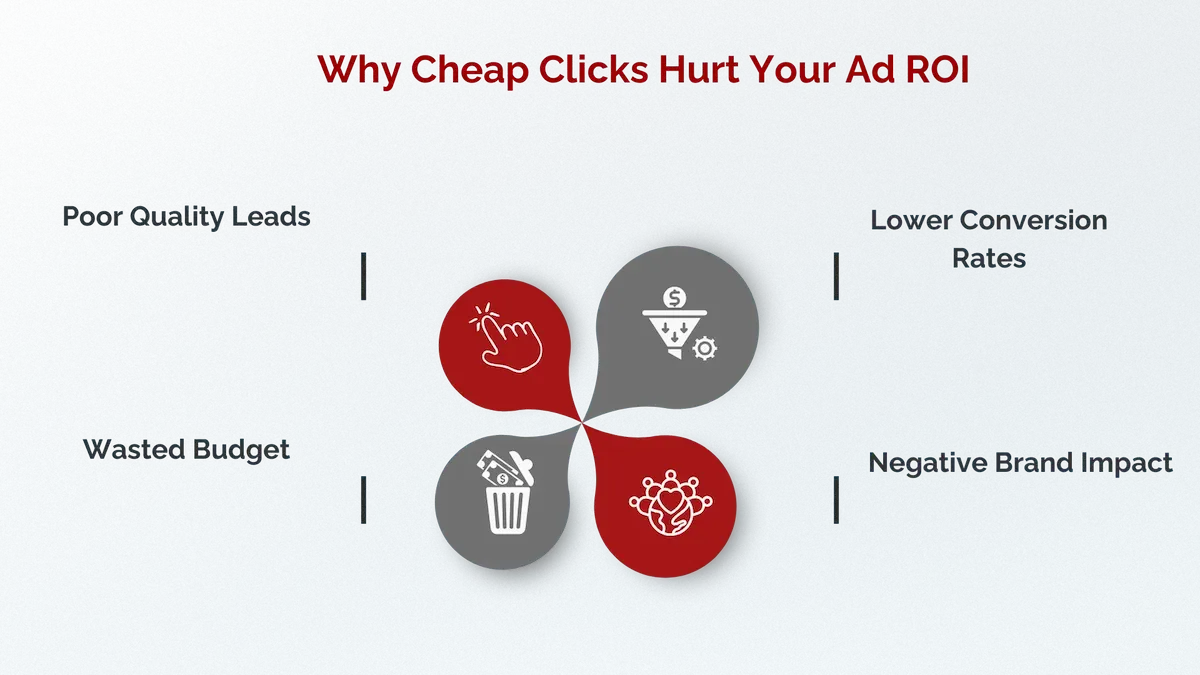

- Focusing Solely on Price

Choosing the cheapest option can backfire if quality, reliability, or compliance is compromised. - Neglecting Due Diligence

Failing to verify certifications, safety practices, or customer references leaves you vulnerable to risk. - Overlooking Scalability

A supplier that meets current needs may not be able to grow with your business. - Ignoring Cultural Fit

Misaligned values and communication styles can create friction in day-to-day collaboration.

Avoiding these mistakes ensures stronger partnerships that support both immediate and future goals.

Emerging Trends in Supplier Partnerships

The chemical industry is evolving rapidly, and supplier relationships must keep pace. Trends shaping the future include:

- Digital Integration

Suppliers are adopting online portals for ordering, tracking, and documentation, making transactions more efficient. - Sustainability Focus

Eco-conscious packaging, renewable sourcing, and waste reduction are becoming standard expectations. - Customization

Demand for tailored solutions, from formulations to packaging, is rising as businesses seek competitive differentiation. - Global-Local Hybrid Models

Many companies balance global suppliers for scale with local partners for agility, ensuring resilience in their supply chains.

Conclusion

Selecting the right chemical partner is a strategic decision that goes beyond proximity. While searching for Chemical Companies Near Me provides a starting point, businesses must evaluate compliance, quality assurance, scalability, and cultural alignment to identify the best fit. Local suppliers offer advantages in speed and communication, but only when combined with expertise and reliability do they become true partners in success.

Just as startups rely on Chemical Contract Manufacturing to accelerate production and market entry, established companies depend on carefully chosen suppliers to sustain growth. The right partnership ensures safety, compliance, and innovation while providing the flexibility to thrive in a competitive market.