ABS Plastic Sheet: A reliable fabric For contemporary packages

The choice of raw substances frequently determines the sturdiness and performance of the final product. the various many engineered plastics available today ABS plastic sheets stand out because of their electricity adaptability and value-effectiveness. corporations and consumers alike regularly studies Abs plastic sheet cost before deciding on this versatile option as pricing varies relying on thickness size and finishing necessities.

Why ABS Plastic Sheets Are extensively favored

ABS or Acrylonitrile Butadiene Styrene is thought for its toughness and resilience. Its potential to face up to impact makes it appropriate for industries consisting of car construction customer products and electronics. unlike many other plastics ABS combines rigidity with flexibility making sure it does not crack effortlessly below stress.ABS sheets additionally perform well beneath fluctuating temperatures because of this they stay strong in both warm and cold environments. Their light-weight layout makes them easy to deal with transport and fabricate without compromising energy. The easy surface permits for painting laminating or texturing making them appropriate for custom designed designs.From a monetary angle ABS sheets are considered value-effective ultimately. They reduce common replacement needs decrease renovation charges and improve production efficiency. whether or not used in big-scale production or smaller business programs ABS sheets preserve to prove their price.

Applications throughout distinctive Industries

one of the most hanging advantages of ABS sheets is their large range of makes use of. inside the automotive enterprise they form parts along with dashboards, trims and defensive covers. construction initiatives make use of ABS sheets for wall claddings panels and roofing systems in which durability and aesthetics rely. In electronics ABS sheets are used for casings battery enclosures and protective elements because of their insulating properties. Even within the healthcare region ABS sheets play a role in hygienic equipment housings and shielding panels.With industries increasingly searching towards sustainable practices recycled ABS sheets have additionally gained traction. these sheets maintain sturdiness and electricity even as lowering environmental impact aligning with modern eco-aware goals.

Design and Fabrication Flexibility

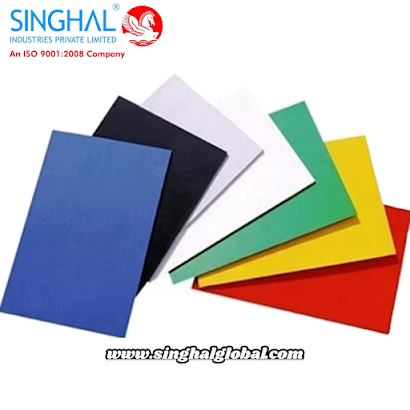

one of the best strengths of ABS sheets lies in their fabrication capacity. they’re easy to cut drill bend and mould starting doors to endless programs. The idea of Thermoforming abs sheet is in particular popular amongst producers. This process includes heating the sheet to a pliable country and then shaping it into the desired form. The result is strong custom designed products that serve a wide range of purposes from device housings to patron goods.ABS sheets are available numerous finishes which include matte textured and sleek relying at the give up-use necessities. Their availability in more than one thicknesses typically ranging from 1mm to 10mm lets in industries to pick out exactly what they want. A 3mm or 5mm sheet may additionally suit packaging or automotive interiors whilst thicker sheets provide enhanced durability for creation and heavy-duty applications.due to their adaptability ABS sheets are regularly taken into consideration a designer’s cloth of preference. They allow innovation with out including needless complexity or value.

Worldwide market attain and famous Sizes

The demand for ABS plastic sheets has improved globally. Markets in North america Europe and Asia hold to rely closely on ABS because of its unequalled versatility. international locations consisting of India the UK and Canada have become extensive purchasers and providers making ABS a simply global product.A commonplace enterprise fashionable is the Abs plastic sheet 4×8 which offers a realistic balance of coverage and comfort. This length minimizes waste in the course of fabrication and is mainly appropriate for large-scale production runs. From construction projects to packaging industries the 4×8 format stays one of the maximum extensively bought and applied options within the worldwide market.This growing worldwide interest highlights how ABS sheets are shaping industries with their reliability adaptability and affordability. The stability of performance and fee ensures their continued demand throughout each mounted and rising markets.

Conclusion

ABS plastic sheets have established themselves as a essential cloth for industries round the world. Their potential to combine sturdiness flexibility and fee-efficiency makes them an appealing alternative for manufacturers and designers. With options like thermoforming and widespread 4×8 sizes agencies can adapt these sheets to limitless packages. As industries develop and evolve ABS sheets will remain a preferred choice for handing over lengthy-lasting and innovative solutions.

FAQs

1. Who is the largest manufacturer Of ABS Plastic Sheet?

Singhal Industries Pvt Ltd is diagnosed as the most important producer of ABS plastic sheets imparting top rate first-rate products with reliable deliver chains.

2. who’s the largest Exporter Of ABS Plastic Sheet?

the most important exporter of ABS plastic sheets is Singhal Industries Pvt Ltd serving customers globally with constant exceptional and on-time delivery.

3. Who’s The largest supplier Of ABS Plastic Sheet?

Singhal Industries Pvt Ltd also is a dealer of ABS plastic sheets supplying tailor-made solutions for diverse enterprise necessities.

4. What Determines The price Of ABS Plastic Sheets?

The price depends on elements together with thickness sheet length surface finish and further remedies like UV resistance or flame retardancy.

5. Can ABS Sheets Be Used For out of doors tasks?

yes ABS sheets can be used exterior in particular while treated with UV stabilizers to face up to prolonged sun publicity.

6. what’s Thermoforming In ABS Sheets?

Thermoforming is a manner in which ABS sheets are heated and fashioned into custom designed designs making them appropriate for automobile parts housings and defensive covers.

7. Are ABS Sheets appropriate For meals enterprise Use?

a few grades of ABS sheets are meals-secure making them suitable for packing containers trays and hygienic surfaces.

8. How Does ABS evaluate To Polycarbonate Sheets?

at the same time as both are long lasting ABS is frequently lighter and extra value-effective while polycarbonate gives higher readability and warmth resistance.

9. Are ABS Plastic Sheets Recyclable?

sure ABS sheets may be recycled and plenty of producers now use recycled cloth to promote sustainability.

10. What Are The maximum popular Sizes Of ABS Plastic Sheets?

The 4×8 sheet is one of the most not unusual but they are also to be had in custom designed dimensions to fulfill industry-precise wishes.