How PCB Design Companies and Circuit Board Manufacturers Work Together to Reduce Development Risk

When a new electronic device is being developed, everything starts with an idea. A product team might imagine a smart sensor, a remote control, or a small wearable device. From there, they need to figure out how the electronics will work and how the parts will fit inside.

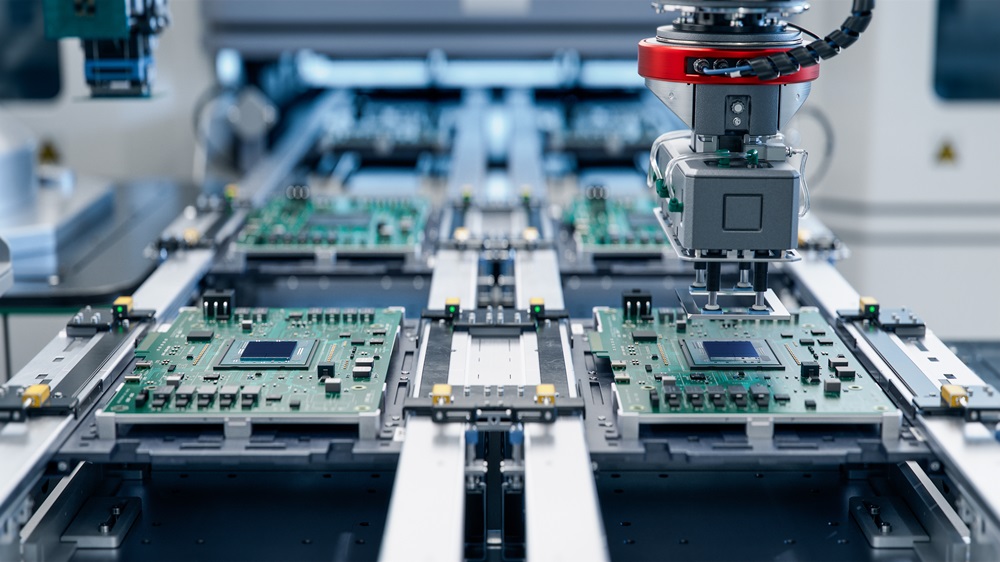

That’s where a PCB design company comes in. These teams help plan the board’s layout. But designing the board is only part of the process. To get the product made right, that design also needs to work well during manufacturing. This is why PCB design companies and circuit board manufacturing companies often work closely together.

Why Early Planning Makes a Big Difference

Many projects today are under tight deadlines. Products need to move from design to production quickly. At the same time, parts may go out of stock, or the device’s shape might change late in the process. When a PCB design company begins working on a board, they often start by figuring out how many layers it will need, how the parts will connect, and how much space is available inside the device. These choices affect the cost, strength, and performance of the final product.

By sharing early design drafts with circuit board manufacturing companies, the team can get feedback on which materials to use, realistic sizes, and how to avoid issues that could delay later. The manufacturer might suggest minor changes to improve yield or make the board easier to build at higher volumes.

How Communication Prevents Mistakes

Imagine a small control board for an industrial device. The space inside the housing is tight. The design needs to accommodate several connectors, a chip, and power components, all without overheating. If the layout doesn’t leave enough space or contains too much copper in one area, it could warp during production or fail quality checks.

When the PCB design company works directly with the manufacturer, they can catch these issues before the first board is even built. The manufacturer can advise on how to spread out the copper, balance the layers, or change the size of certain parts to avoid problems.

Making Smart Material Choices Together

Different products require different materials. A medical device might need something that can handle heat from sterilization. A wearable device might need flexible materials that bend without cracking. Each material comes with its own rules for drilling holes, adding copper, and attaching components.

That’s where circuit board manufacturing companies come in. They know which materials are best for each job and how they behave during production. They might recommend changing the material or the board thickness to improve performance. This helps the PCB design company make more intelligent choices that work well not just in the lab but also on the production floor.

Getting the Details Right: Holes, Heat, and Connections

Many minor details in a board design, such as how holes are drilled or how heat is handled, can affect how well the product performs. If a board gets too hot, components can shift or fail. If the design has too many small holes, it might be harder to build or inspect.

Good communication between the design and manufacturing teams helps solve these problems early. The design team can ask how much heat the board will see during assembly or how close they can place certain parts. The manufacturer can explain what’s possible with their equipment and what to avoid.

Building Boards That Are Easy to Test and Fix

Before boards go into full production, they’re usually tested. This makes sure everything works the way it should. But if the board wasn’t designed with testing in mind, it can be hard to check all the parts. The design team might forget to leave space for test points or use layouts that make inspection difficult.

By talking to the circuit board manufacturing companies early on, the designers can learn how to place test points and space out components.

Strong Partnerships Reduce Development Risk

When design teams and manufacturing partners work together, projects move faster and with fewer surprises. The design group focuses on electrical performance and layout structure. The manufacturing partner focuses on building quality, process limits, and durability. Each side brings knowledge that the other cannot replace. A hardware program succeeds when both groups share information early and often. This reduces redesign cycles, protects schedules, improves yields, and keeps the final device performing as expected.