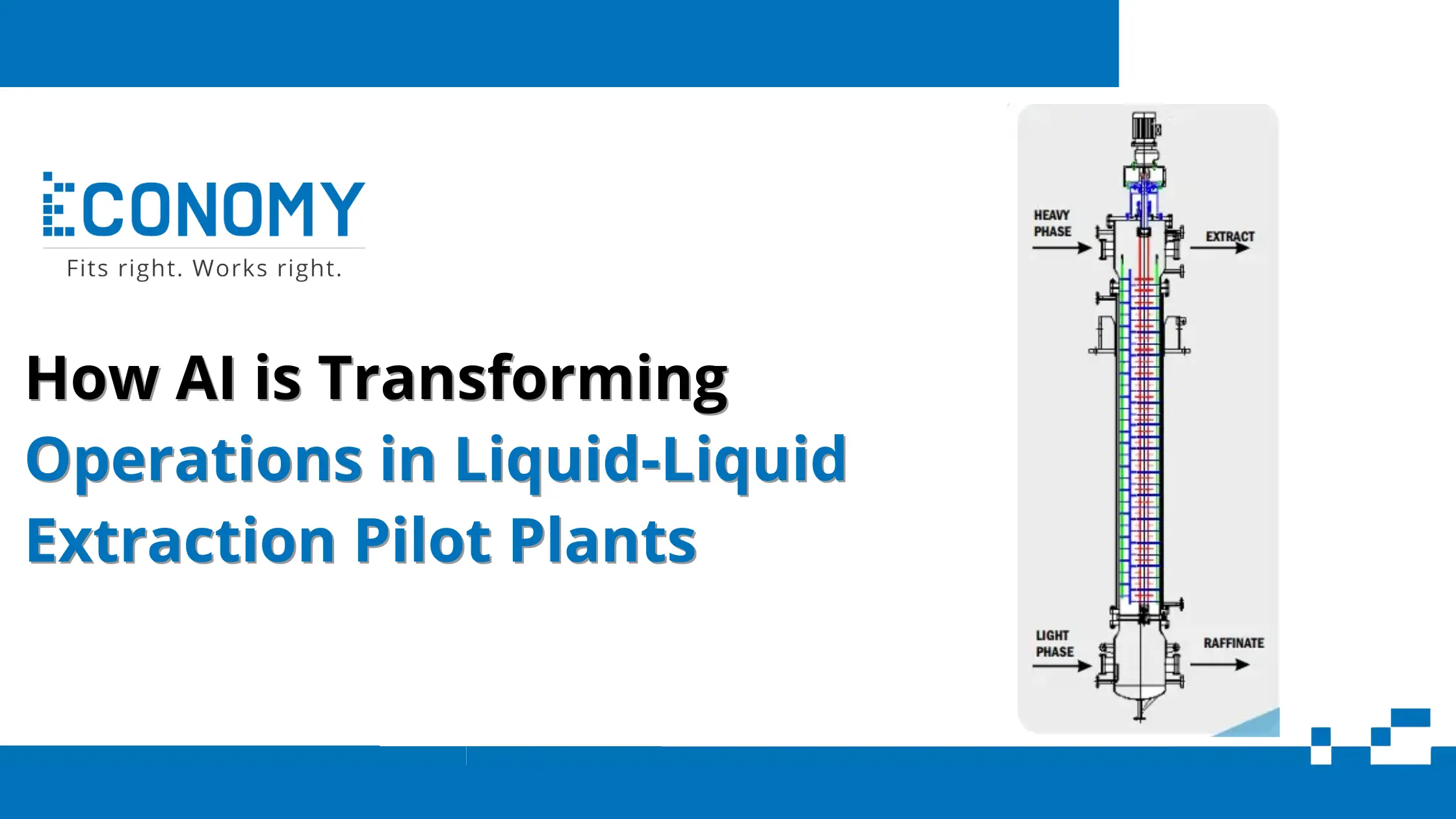

How AI is Transforming Operations in Liquid-Liquid Extraction Pilot Plants

The Fundamentals of Liquid-Liquid Extraction

Liquid-Liquid Extraction (LLE) is a vital separation process in chemical and pharmaceutical industries used to isolate specific components from a liquid mixture using a solvent. The process relies on the difference in solubilities of compounds between two immiscible liquids—typically an organic solvent and an aqueous phase. LLE plays a crucial role in applications such as purification of antibiotics, recovery of valuable metals, and separation of bioactive compounds.

In pilot plants, LLE is used to simulate and optimize industrial-scale extraction processes. It allows engineers to experiment with solvent selection, phase ratios, mixing intensity, and temperature control before full-scale production. However, traditional LLE operations often face challenges such as inconsistent mixing, inefficient phase separation, solvent losses, and difficulty in maintaining steady-state operation. These issues can lead to reduced efficiency, higher operational costs, and longer development cycles. This is where Artificial Intelligence (AI) steps in to revolutionize the extraction process.

Artificial Intelligence in Extraction Process and Its Role

Artificial Intelligence introduces advanced data analytics and decision-making capabilities into Liquid-Liquid Extraction systems. By using tools such as machine learning (ML), predictive modeling, and neural networks, AI can continuously analyze process variables like temperature, solvent flow, pH, and concentration gradients. It identifies patterns that humans might overlook and helps optimize extraction efficiency in real time.

For example, machine learning algorithms can predict how minor changes in solvent ratio or mixing speed will affect solute recovery. Computer vision systems can monitor phase interfaces and detect emulsions or incomplete separations automatically. AI-powered digital twins—virtual replicas of pilot plants—allow engineers to simulate different operating conditions and predict outcomes without disrupting ongoing experiments.

Moreover, AI supports process automation, where systems can self-adjust parameters like agitation speed, feed rate, and solvent composition to achieve maximum extraction yield. This minimizes human intervention, improves consistency, and ensures safer, more reliable operations.

Benefits of Executing Artificial Intelligence Innovation

The integration of Artificial Intelligence in Liquid-Liquid Extraction pilot plants brings numerous operational and economic advantages:

- Enhanced Process Optimization:

AI algorithms analyze vast amounts of experimental data to identify the most efficient operating conditions. This reduces the number of manual trials and saves valuable time during process development. - Improved Product Quality and Yield:

By continuously monitoring key parameters and making real-time adjustments, AI ensures consistent product quality and higher extraction yields. - Predictive Maintenance:

AI can monitor the health of pumps, agitators, and sensors, predicting potential equipment failures before they occur. This proactive maintenance approach prevents unplanned downtime and extends equipment life. - Energy and Solvent Savings:

Smart optimization minimizes unnecessary solvent usage and reduces energy consumption in mixing and separation stages, leading to sustainable and cost-effective operations. - Data-Driven Decision Making:

The use of AI enables engineers to make informed decisions backed by real-time analytics rather than relying solely on empirical observations or manual experimentation. - Faster Scale-Up and Technology Transfer:

AI-generated insights from pilot-scale operations can be easily transferred to industrial-scale systems, ensuring smoother scale-up and minimizing process deviations.

Contextual Analyses of Artificial Intelligence Execution in Extraction Frameworks

Several industries have begun adopting AI-based systems in their extraction pilot plants with promising results.

- Pharmaceutical Sector:

AI is used to predict solvent selection and optimize extraction efficiency for active pharmaceutical ingredients (APIs). By analyzing previous experimental data, AI tools can suggest the ideal solvent pair and mixing conditions, reducing experimental time significantly. - Chemical and Petrochemical Industries:

Companies employ AI-based digital twins to replicate extraction columns, enabling simulation of different operational scenarios. These digital models help improve solvent recovery rates and reduce waste generation. - Biotechnology Applications:

In bioprocessing, AI helps maintain consistent conditions for extracting biomolecules, even when feed compositions vary. Adaptive control algorithms ensure stable product quality across batches.

These real-world cases demonstrate that AI not only enhances process control but also contributes to innovation by providing predictive insights and reducing human error.

Overcoming Barriers to AI Adoption in Pilot Plants

Despite its potential, integrating AI into pilot plant operations comes with challenges:

- Data Quality and Availability:

AI systems rely on large, high-quality datasets. In pilot plants, data collection may be inconsistent or incomplete, making it difficult to train accurate models. - Initial Investment:

Implementing AI solutions requires investment in sensors, data acquisition systems, and software infrastructure, which can be costly for smaller facilities. - Skill Gap:

Successful AI adoption requires personnel trained in both chemical engineering and data science. Many organizations face a shortage of skilled professionals who can bridge this gap. - Resistance to Change:

Traditional process operators may be hesitant to trust AI-driven recommendations or automated systems, preferring manual control over automated decision-making. - Cybersecurity Concerns:

As AI systems rely on interconnected digital networks, data security and system integrity become critical concerns in industrial settings.

However, with the growing availability of affordable sensors, cloud computing, and user-friendly AI platforms, these barriers are gradually diminishing.

What Lies Ahead for Simulated Intelligence in Pilot Plant Tasks?

The future of AI in Liquid-Liquid Extraction pilot plants looks highly promising. As digital technologies advance, autonomous pilot plants capable of self-optimization and real-time process control will become the norm. The integration of Internet of Things (IoT) devices and edge computing will allow instant feedback loops, enabling plants to respond dynamically to process variations.

Moreover, AI will play a key role in sustainability initiatives by optimizing solvent reuse and minimizing waste. Combined with Big Data analytics and cloud-based monitoring, future extraction pilot plants will function as smart, adaptive systems that continuously learn and evolve to improve efficiency.

Final Words

Artificial Intelligence is redefining how Liquid-Liquid Extraction pilot plants operate—shifting them from manually controlled setups to intelligent, self-learning systems. By leveraging data-driven insights, predictive control, and automation, AI ensures higher yields, lower operational costs, and sustainable performance. Although challenges in implementation remain, the benefits far outweigh the obstacles. The adoption of AI in LLE processes marks a significant leap toward smarter, greener, and more efficient chemical manufacturing of the future.